The next evolution of sophisticated luxury is here with the introduction of the GS-6 Series from Karma Automotive, a southern California-based producer of luxury electric vehicles. The first model to be produced in the new series is called the GS-6, and while it will retain the same exotic design of the award-winning Revero GT®, it will be offered at a more attainable price point for drivers who want the environmental benefits of an electric vehicle, without sacrificing design or performance.

“Our brand promise at Karma has always been to provide high-end luxury vehicles and technologies that are driven by innovation and inspire our drivers’ ambitions with new and unique offerings,” said Dr. Lance Zhou, PhD, Karma’s CEO. “As we look to the future, we believe we will change the world of mobility by making luxury electric vehicles more accessible.”

The combination of stimulating design, confidence-inspiring driving and technology, and an aggressively-priced manufacturer’s suggested retail price (MSRP) starting at $83,900*, the GS-6 extended range electric vehicle (EREV) is a formidable competitor in the “new luxury” sedan segment. Available now, the GS-6 is offered in three variants: Standard, Luxury, and Sport, with the anticipated all-electric GSe-6, the brand’s first-ever pure battery electric vehicle (BEV), available later in the year starting at $79,900*.

All GS-6 models benefit from the exclusive design and craftsmanship that Karma Automotive is known for, while offering high-tech customization that allows every Karma to be personal and special to its owner. The GS-6 family is available with convenience and safety features including an Advanced Driver Assistance System (ADAS) which features Adaptive Cruise Control (with “Stop & Go” feature), Lane Keep Support (LKS, with hands-off detection/warning and haptic steering wheel response for unintended lane departure), Automatic Emergency Braking (AEB), Blind Spot Monitoring (BSM) and Rear Cross Traffic Alert (RCTA), 360-degree Surround View Cameras System (SVCS), and Parking Distance Monitoring (PDM). The haptic steering wheel can also control audio and phone functions, cameras, driving modes, the adaptive cruise control and the 3-mode regenerative braking system. The GS-6 also has heated power side view mirrors, eight airbags, an anti-theft alarm, Over-the-Air (OTA) remote diagnostics and software update functionality, Bluetooth, Apple CarPlay®, Android Auto™, and integrates Karma mobile app support.

The GS-6 Series has Karma’s class-leading powertrain and new vehicle warranty: 8-year/80,000-mile powertrain limited warranty; 4-year/50,000-mile new vehicle limited warranty; 6-year unlimited anti-corrosion/perforation limited warranty; and 4-year/50,000 mileage roadside assistance program.

Confidence-Inspiring Performance

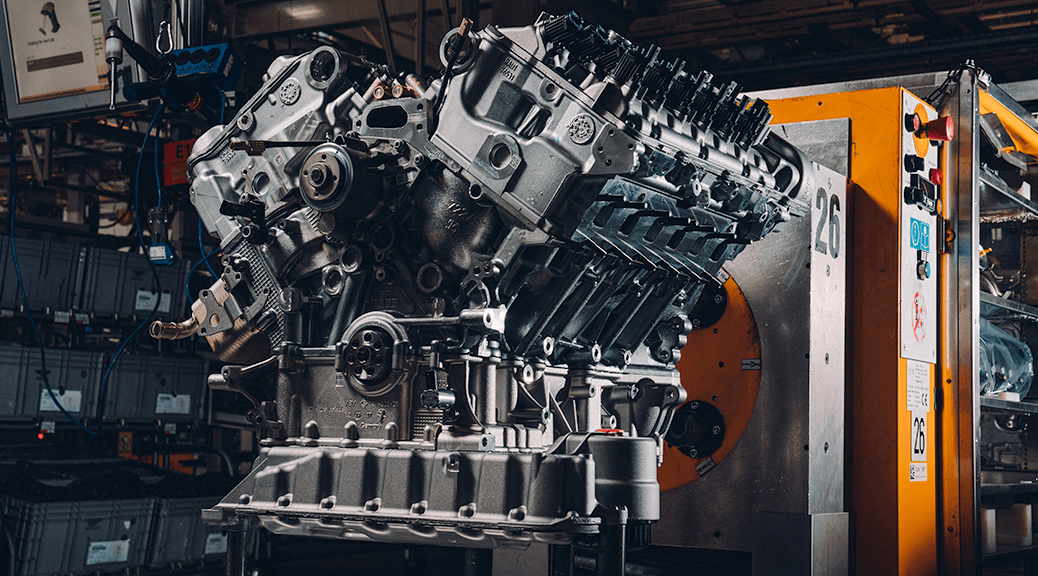

Assembled at Karma’s Innovation and Customization Center (KICC) in Moreno Valley, California, which has offered world-class engineering, design, customization and manufacturing services along with electrification platforms since it opened in 2017. The 28 kW HV battery pack together with a 1.5-liter turbocharged powerplant mated to an onboard generator provides electricity to the 400 kW 2-motor propulsion system that offers a compelling combination of drivability, performance and efficiency. This setup provides 536 horsepower and 550 lb-ft torque. All options incorporate Karma’s advanced regenerative braking system.

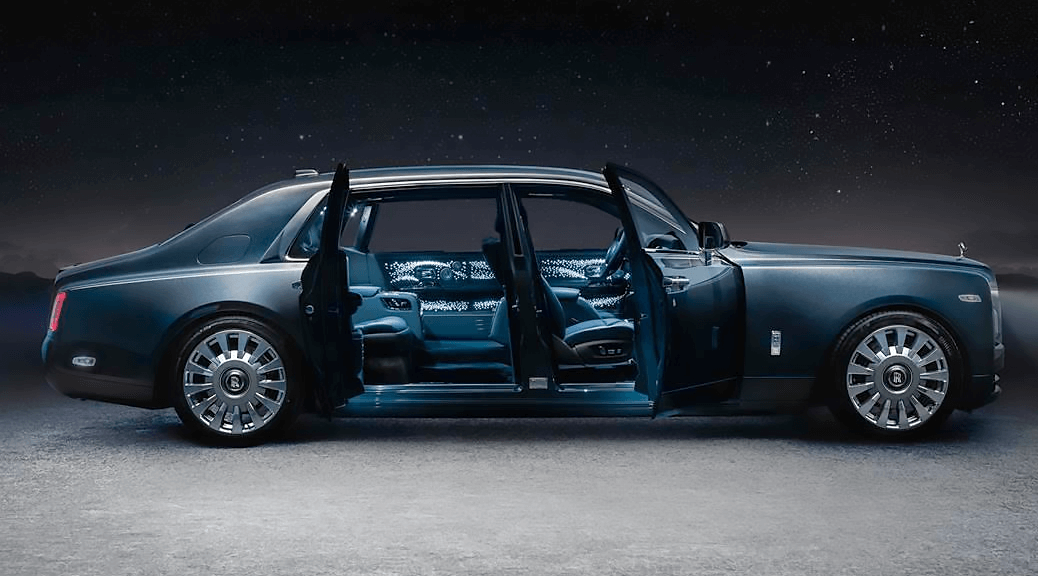

Beautiful, Functional Design

Karma vehicles have a long and well-established reputation for excellent design and the GS-6 is no exception with focused customization options, including elements like reclaimed wood salvaged from California wildfires, carbon fiber and a range of five interior leather color combinations. New for 2021, Karma has introduced two new exterior colors – Saguaro Green and Imperial Copper – that will join a diverse palette comprised of 10 other California-themed hues. The GS-6 will also offer a black-out option and various exterior carbon fiber elements.

The GS-6 and GS-6L will come standard with 21-inch Cascade Silver wheels and slate-colored Brembo disc brake calipers, while the top-of-the line GS-6S will come standard with 22-inch Dune Twist Midnight Chrome wheels with red Brembo calipers mated to vented discs. Optional caliper colors also include silver, blue, yellow and two shades of orange and certain trim levels include options for either 21- or 22-inch wheels and surface finishes.

Human Machine Interface (HMI)

The high-resolution connected displays in the GS-6 serve as the information hubs for tech-forward drivers, controlling the vehicle systems such as steering feel, accelerator pedal aggressiveness, ADAS behavior, HVAC, audio functions, camera displays, and other vehicle systems. Using Bluetooth connectivity, a driver’s phone can used to activate Apple CarPlay™, Android Auto™ and their in-car ecosystems. In addition, the center display on the GS-6 features personalized comfort zones for heated and vented seats, mirrors, temperature, audio and lighting.

Upon accessing the “Energy” page via the center-mounted touch-screen, the driver can enter “Track Mode” which provides several statistics including energy flow, tire pressure and temperature, speed, torque, lap times, g-forces, energy usage, battery function, engine temperature, fuel usage and driving history. The “Driver Stats” page holds the vehicle’s achievement records and can encourage them to “beat” their previous records for racetrack environments or driving efficiency.

The “Energy History” page provides current and historical energy usage, where energy-conscious drivers can monitor the vehicles efficiency over various trips and receive an energy efficiency score, as well as displaying a multitude of other dials and data points.

Karma App

The Karma app functions as a controller offering drivers access to the vehicle’s location, remote preconditioning, door lock-unlock, charge scheduling, vehicle health reporting and an Augmented Reality (AR) user manual.

Firmware Over the Air (FOTA)

Cellular connectivity provides bidirectional software connectivity for remote diagnostics and continuous updates and upgrades helping the vehicle systems remain current and even improve over time.

Karma Extended Range EV Technology

The GS-6 is designed as an “extended-range electric vehicle” or “EREV” to help mitigate consumer range anxiety fears. This range extender setup uses an on-board generator to create electricity which powers the motors propelling the wheels. The vehicle utilizes a transversely mounted, twin-motor, Rear Drive Module (RDM) that includes torque vectoring in the GS-6S variant. The 28-kWh battery pack is good for up to 80 miles of pure electric range and 360 miles of total range[1].

The GS-6 uses inverters developed in-house by Karma’s powertrain team that converts DC current from the battery pack and/or generator to power the AC drive motors, and to capture AC power from the regenerative braking system to recharge the battery pack. A single-speed gearbox sits between the twin motors. Because the inverters are integrated with the drive motors, the RDM is an extremely compact and lightweight package.

Three Driving Modes

An efficient, three-cylinder, 1.5-liter, turbocharged powerplant acts as the GS-6’s range-extender. In “Stealth” driving mode, the vehicle is powered by the battery only. In “Sustain” mode, the generator creates electricity to power the vehicle. In “Sport” mode, power is provided to the traction motors from both the battery and the generator. To enhance the driving experience, Karma also implemented an active exhaust system specifically programmed to provide a throaty, sporty note when driving in Sport mode.

Safety is a Priority

To further enhance driver confidence and with vehicle safety at the top of customers’ purchase considerations, Karma has developed and integrated several Advanced Driver-Assistance Systems (ADAS) safety features in the GS-6, including the following technologies:

- Lane Keeping Assist (LKA) – Combine a forward-facing camera to detect lane markings with an electric steering system, alerting drivers through haptic feedback when they are about to cross lines.

- Lane Keeping Support (LKS) – Combine a forward-facing camera to detect lane markings with an electric steering system, actively keeping the vehicle in the center of the lane.

- Automatic Emergency Braking (AEB) – Automatically steps in to prevent a collision and is a vital piece of safety technology in all new Karma products.

- Adaptive Cruise Control (ACC) with “Stop & Go” feature – Accelerates or brakes to maintain a set distance from the car ahead to relieve the stress of operating the accelerator pedal in many cruising conditions. The ACC system can bring the vehicle to a complete stop in normal traffic situations with ‘Resume’ available for extended stops.

- Blind Spot Monitor – Vehicle-based sensors that detect other vehicles located to the driver’s side and rear and provides user-selectable visual, audible, and haptic steering wheel warnings.

- Curve Adaptive Headlights – As the driver turns the steering wheel left or right the headlights pivot in that direction to better illuminate what’s in the vehicle’s path and a side camera view can be shown on the center display.

- Surround View Camera System – Front and rear cameras, side view curb cameras, and a 360-degree overhead vehicle view combine to provide a birds-eye view of your car on the center display. The visual information is reinforced with audible warnings if the vehicle is too close to an obstruction.

More Attainable Pricing

As previously announced, the Revero GT nameplate will be moving up-market in future variants, while the GS-6 will now occupy a slot in the Karma lineup at a much more attainable price-point for entry luxury buyers.

“We’re proud that we have been designing, engineering, producing, selling and servicing luxury EV vehicles for years now, which is something other EV startups can’t say,” said Joost de Vries, Karma’s VP of Global Sales and Customer Experience. “The GS-6 with its more attainable price point, combined with a long list of standard and available convenience features and luxurious design, will appeal to a much larger audience.”

The GS-6 Series

In addition to the GS-6 EREV, 2021 will see Karma Automotive offer it’s first-ever all-electric vehicle, the GSe-6. With a starting manufacturer’s suggested retail price of $79,900*, the U.S.-built vehicle will include a new all-battery powertrain configuration expanding the automaker’s reach in the competitive pure EV market.

Drivers who are interested in securing their GSe-6 please contact one of our Karma specialist.